Cost Containment Strategies for Procurement

As the world faces global inflation, procurement teams in the pharmaceutical industry must find ways to manage cost containment across their suppliers.

Here are some strategies for how to achieve better cost control without compromising quality.

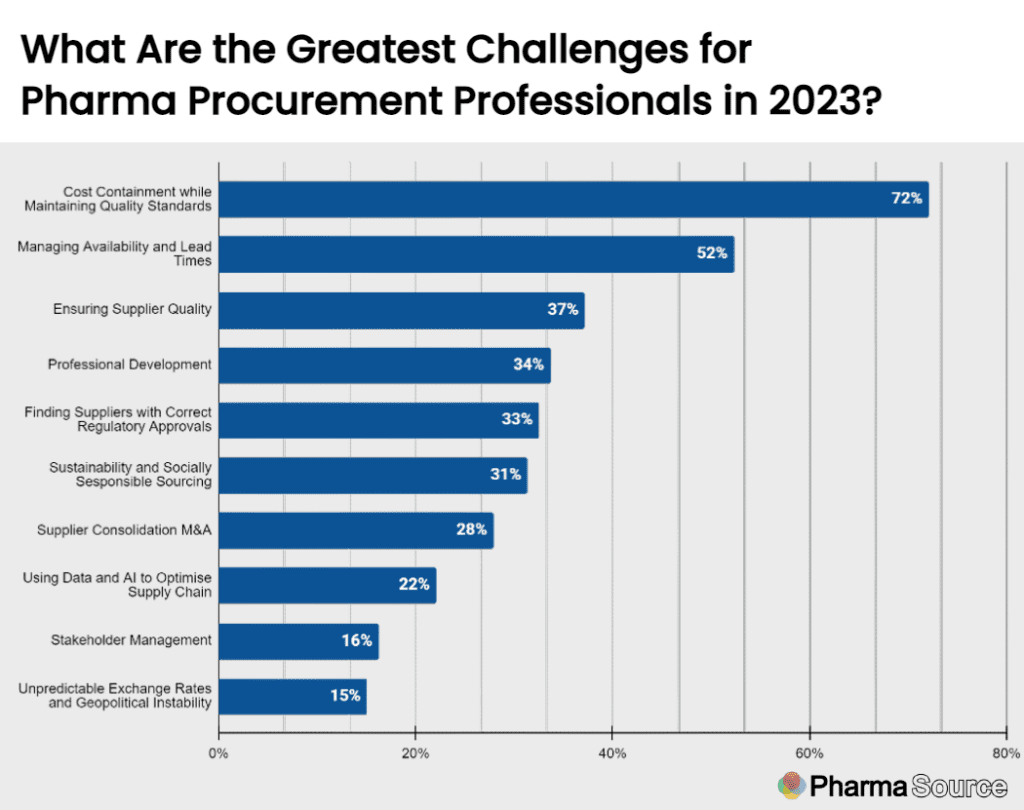

Procurement professionals consistently report that cost savings is a top priority. In this recent PharmaSource survey, “cost containment while maintaining quality standards” was highlighted as the greatest challenge facing procurement in 2023.

In this guide we will cover:

A definition of Cost Containment

10 Cost Containment strategies

Risks and Challenges with Cost Containment

Cost Containment definition

Cost containment refers to the set of strategies and tactics that organizations use to control or reduce their expenses.

In the context of procurement, cost containment typically refers to efforts to reduce the cost of goods and services purchased from suppliers, while maintaining or improving quality and value. This can include negotiating better prices, optimizing procurement processes, identifying opportunities for savings, and leveraging technology and data analytics to improve efficiency and reduce costs.

Cost containment is important for organizations that are looking to improve their bottom line, increase profitability, and maintain a competitive edge in the marketplace.

“Watch the costs and the profits will take care of themselves.”

Andrew Carnegie

Cost Containment strategies

Here is a playbook that outlines some tried-and-tested methodologies that can be used to achieve this goal:

1. Conduct a thorough spend analysis

Before taking any cost containment measures, procurement teams must conduct a detailed spend analysis to identify the areas where they can save costs without compromising on quality. This analysis will help in identifying the suppliers who contribute the most to the organization’s spend, as well as those with the highest price increases.

- Gather data on all the procurement spend categories.

- Categorize spend by supplier, product, and service.

- Analyse the spend data to identify trends and areas of potential cost savings.

- Use the analysis results to prioritize procurement efforts and focus on high-cost areas.

Incorporate a “total cost of ownership” approach, considering not only the initial purchase price but also the long-term costs associated with the product or service, such as maintenance, repair, and replacement costs. By evaluating the total cost of ownership, procurement teams can make informed decisions that result in cost savings over time.

2. Rationalise the supplier base

Based on the results of the spend analysis, procurement teams should rationalise their supplier base. This process involves identifying the number of suppliers they have for each product or service and consolidating their supplier base to fewer, more strategic suppliers.

Consolidate the number of suppliers used for a particular product or service to reduce transaction costs and increase negotiating power. This can result in lower prices and improved supplier relationships.

- Identify the various suppliers for each product or service.

- Evaluate each supplier’s performance based on metrics such as cost, quality, delivery time, and service level.

- Determine which suppliers to retain, consolidate, or terminate based on the evaluation results.

- Communicate the changes to suppliers and provide feedback on their performance.

3. Implement strategic sourcing

The procurement team should leverage strategic sourcing to reduce costs. Strategic sourcing involves identifying the best suppliers for each category and negotiating the best terms and prices with them. This process should be done in collaboration with internal stakeholders to ensure that quality is not compromised.

- Develop a sourcing strategy that includes a market analysis, supplier selection criteria, and negotiation tactics.

- Identify potential suppliers using industry databases, referrals, and online searches.

- Send requests for proposals (RFPs) to selected suppliers and evaluate their responses.

- Negotiate with the top suppliers to get the best terms and prices. Negotiate payment terms with suppliers that align with the organization’s cash flow requirements and provide flexibility. This can reduce the risk of cash flow issues and improve the organization’s financial position.

4. Outsource and go global

This well-used approach involves outsourcing products or services to low-cost countries, where labour and materials may be less expensive. However, it’s important to consider the risks associated with global sourcing, such as quality and sustainability, supply chain disruptions, and ethical concerns.

5. Implement digital sourcing tools:

Marketplaces and digital sourcing tools can automate the bidding process, reduce cycle times, and increase transparency. These tools allow procurement teams to compare bids easily, reducing the time and effort involved in procurement processes. This technology should be used to maximise the procurement team’s efficiency and optimise the supplier selection process.

- Research e-sourcing tools that meet the organization’s needs.

- Evaluate the features of the tools to identify the most suitable one for the procurement team.

- Train the procurement team on how to use the e-sourcing tools.

- Implement the e-sourcing tool and integrate it with the organization’s procurement software.

6. Optimise inventory management

Procurement teams must have a clear understanding of the organisation’s inventory levels and how they impact supplier relationships. A well configured ERP with the use of analytics and other technological tools, teams can track inventory levels and identify opportunities for optimization to reduce the number of orders and storage costs.

- Collect data on inventory levels, lead times, and demand patterns.

- Analyse the data to identify opportunities for inventory optimization.

- Use analytics tools to forecast demand and optimize inventory levels.

- Implement a vendor-managed inventory (VMI) system to improve inventory management.

- AI and machine learning can help analyze procurement data to identify patterns and insights that may not be immediately apparent to human analysts. This can help procurement teams make more informed decisions that result in cost savings.

7. Collaborate with your suppliers

Procurement teams can work collaboratively with suppliers to identify cost-saving opportunities without compromising quality. These opportunities can be found in areas such as process optimization, waste reduction, and innovation. Such initiatives not only reduce costs but can also lead to long-term relationships with suppliers.

- Identify suppliers that are willing to collaborate on cost-saving initiatives.

- Develop a collaborative relationship with suppliers to share ideas and best practices.

- Set clear objectives and goals for the collaboration.

- Measure the results of the collaboration and provide feedback to suppliers.

8. Apply a “value engineering” approach

Work with suppliers to identify and eliminate unnecessary costs from the supply chain while maintaining or improving product quality and functionality. This approach involves analyzing the components of a product or service and exploring alternative materials, designs, and manufacturing processes that can reduce costs.

9. Implement cost sharing mechanisms with suppliers

Procurement teams can negotiate cost-sharing mechanisms with suppliers to minimize the impact of price increases. This can be done by sharing the risks and rewards of the market with suppliers, with a win-win agreement.

- Analyse the supplier’s cost structure and determine the impact of price increases.

- Develop a cost-sharing mechanism that shares the risks and rewards of the market with the supplier.

- Negotiate with the supplier to agree on the cost-sharing mechanism.

- Review the mechanism regularly to ensure that it is effective.

10. Continuous Improvement

Finally, procurement teams should focus on continuous improvement by reviewing and updating procurement policies and processes, continuously monitoring market trends, and adopting new technology and practices.

- Develop a continuous improvement plan that includes periodic reviews of procurement policies and processes.

- Use feedback from stakeholders to identify areas for improvement.

- Monitor market trends and technology advancements to identify new opportunities.

- Implement changes and evaluate the results of the continuous improvement efforts.

A “lean” procurement process involves identifying and eliminating waste in the procurement process, such as unnecessary paperwork, inefficient processes, and overproduction of materials. By streamlining the procurement process, organizations can reduce costs and improve efficiency.

The pharmaceutical industry must navigate the global inflation crisis with a well-planned procurement strategy that focuses on cost containment while maintaining quality. Procurement teams should leverage their expertise, analytics, and technology to streamline their operations, build strong relationships with suppliers, and optimize procurement processes to reduce costs.

Risks and Challenges with Cost Containment

There are several potential risks and challenges associated with cost containment in procurement. Here are a few examples and some strategies for addressing them:

1. Compromising on Quality

In their efforts to cut costs, procurement teams may be tempted to select suppliers based solely on price, rather than on quality or other factors. This can lead to problems down the road if the supplier fails to meet expectations or delivers subpar products or services. To address this risk, procurement teams should prioritize quality and value over price alone, and work closely with suppliers to ensure that their expectations are clear and that quality standards are met.

2. Supplier Relationships

Cost containment strategies can strain relationships with suppliers if they feel they are being squeezed too hard or are not being given a fair deal. This can lead to a breakdown in communication, a decline in quality, or even the loss of a key supplier. To address this risk, procurement teams should focus on building strong relationships with suppliers based on trust, transparency, and mutual benefit. Regular communication, fair negotiation, and a willingness to collaborate can go a long way in maintaining positive relationships with suppliers.

3. Market Volatility

Economic and market conditions can change rapidly, making it difficult to predict pricing and availability of goods and services. This can make it challenging for procurement teams to secure the best deals and contain costs. To address this risk, procurement teams should stay informed about market trends and conditions, maintain a diversified supplier base, and be flexible and adaptable in their approach to procurement.

4. Lack of Visibility

Procurement teams may struggle to identify opportunities for cost containment if they lack visibility into spending across different categories, suppliers, and departments. This can lead to missed opportunities for savings and inefficiencies in procurement processes. To address this risk, procurement teams should invest in data analytics tools, spend analysis software, and other technologies that provide visibility into spending patterns and supplier performance.

5. Internal Resistance

Procurement teams may face resistance from internal stakeholders who are resistant to change or who prioritise other objectives over cost containment. This can make it difficult to implement cost containment strategies and achieve buy-in from key decision-makers. To address this risk, procurement teams should engage stakeholders early in the process, communicate the benefits of cost containment clearly, and demonstrate the value of procurement initiatives through data-driven metrics and success stories.

By addressing these and other risks and challenges, procurement teams can successfully implement cost containment strategies that deliver long-term value to their organisations.

Cost Containment metrics

There are several metrics that procurement teams can track to measure the effectiveness of their cost containment efforts. Here are a few examples:

1. Cost Savings

This is the most obvious metric for measuring cost containment, and refers to the total amount of money saved by the organisation through procurement initiatives. This can be calculated by comparing the actual cost of goods or services to the expected or budgeted cost.

2. Spend Analysis

Spend analysis metrics measure spending patterns across different categories, suppliers, and departments. This information can be used to identify opportunities for cost containment and to optimise procurement processes.

3. Supplier Performance

Supplier performance metrics measure the quality, timeliness, and reliability of suppliers. By tracking supplier performance, procurement teams can identify opportunities for improvement and negotiate better deals.

4. Maverick Spend

Maverick spend refers to purchases made outside of the established procurement process, such as purchases made by individual employees or departments. By tracking maverick spend, procurement teams can identify opportunities to improve compliance with procurement policies and reduce unnecessary spending.

5. Contract Compliance

Contract compliance metrics measure the extent to which suppliers are adhering to the terms of their contracts. By tracking contract compliance, procurement teams can ensure that they are getting the best value from suppliers and avoiding overpayments or other issues.

6. Total Cost of Ownership

Total cost of ownership metrics measure the total cost of a product or service over its entire lifecycle, including procurement, maintenance, and disposal costs. By considering the total cost of ownership, procurement teams can identify opportunities to reduce costs over the long term.

By tracking these and other metrics, procurement teams can gain visibility into their spending patterns, supplier performance, and overall cost containment efforts. This information can be used to identify opportunities for improvement, optimise procurement processes, and demonstrate the value of procurement initiatives to key stakeholders.

Is there anything missing from this guide? If you have any best practices to add, please get in touch