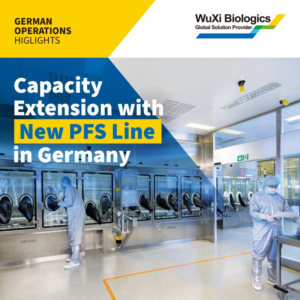

- Catalent has expanded its clinical supply facility in Schorndorf, Germany, adding 32,000 square feet of space.

- The expansion includes new temperature-controlled storage and an automatic bottle filling line.

Catalent, Inc., enabling the development and supply of better treatments for patients worldwide, has completed the expansion of its clinical supply facility in Schorndorf, Germany. This site is Catalent’s flagship European facility and provides comprehensive clinical supply services, including packaging, storage, and distribution.

The expansion has increased the site’s footprint by 32,000 square feet (3,000 square meters). This additional space will be used for the storage and handling of clinical trial supply materials at controlled room temperatures between 15 and 25 degrees Celsius. The original building now accommodates a new, fully automatic bottle filling line and a dedicated area for Catalent’s FastChain® demand-led supply service. These enhancements aim to maintain a high level of service for Catalent’s pharmaceutical and biotech customers.

Lorenzo Carletti, President of Clinical Development & Supply at Catalent, stated, “The Schorndorf site plays an important role in the strategic focus of the company and our ability to meet customer demand for clinical packaging solutions, including temperature-controlled services. We are pleased to bring additional capacity to the site for temperature-controlled storage and Catalent’s FastChain service so that we can meet the current and future needs of our customers.”

Opened in 1996, Catalent’s Schorndorf facility offers a range of clinical supply services, including multilingual project services, comparator sourcing, primary and secondary packaging, labeling, clinical storage, distribution, and returns and destruction. The site also provides late-stage pharma product development and commercial services, such as oral solid dose manufacturing and specialty packaging.

Catalent’s FastChain service is a continuous Good Manufacturing Practices (GMP) approach that decouples primary from secondary packaging, enabling timely and cost-effective adaptation and regional supply of clinical materials on demand.

Overview of outsourcing trends

Overview of outsourcing trends