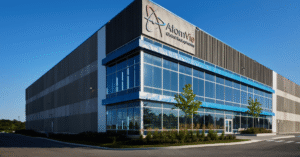

Founded in June 2020, INCOG has secured FDA-approval and now establishes itself as a new force in contract manufacturing with a focus on sterile injectables.

As we gear up for CDMO Live, we had the opportunity to speak with Cory Lewis, CEO, President, and Founder of INCOG Biopharma Services, about their dedicated approach to serving customers in the high-growth sterile injectable market.

Despite the company only being four years old, INCOG’s leadership team brings decades of industry experience. Cory says he has brought the ‘band back together’ by reuniting seasoned professionals to create a tier-one contract manufacturing organisation (CDMO).

“Our goal is to compete at the highest level, and that requires a seasoned executive team with a robust investment strategy.”

INCOG’s investments in vial, syringe, and cartridge filling capabilities are “just the beginning” says Cory.

“We’re also expanding into quality control, lab stability services, and eventually, auto-injector device assembly and final packaging. Our long-term site master plan outlines our ambition to not only enhance filling capacity, but also integrate additional business units to support commercial packaging and device assembly.”

INCOG recently secured their first FDA approval, which signals a turning point for the contract manufacturer.

“Our first FDA approval, achieved less than eighteen months after production began, is a testament to our operational and quality excellence. This milestone was marked by an eight-day inspection with zero observations, a rare accomplishment in our industry.”

Investing in the Future

“Our first facility, operational since 2022, features a multi-use line catering to traditional molecules. We’re not limited to high potency or live viruses, which allows us to serve a broad range of needs. The upcoming high-speed syringe line will significantly increase our annual capacity, emphasising our commitment to growth and innovation.

INCOG’s pipeline is predominantly focused on biologics and peptides, “high-value molecules that benefit from our investment in minimising line loss. This is crucial when dealing with expensive bulk drug substances, ensuring efficiency and cost-effectiveness for our clients.”

Recent market developments, such as Nova Holdings’ acquisition of Catalent and the BIOSECURE Act legislation, have presented new opportunities for INCOG. “We’ve welcomed customers transitioning from Chinese manufacturing to our state-of-the-art facilities, further solidifying our position in the market.”

Expanding capabilities

In the past six months, INCOG has expanded its device assembly capabilities, anticipating further investments in this area. This includes everything from syringe accessorising to auto-injector assembly.

“Approximately 40% of our pipeline programs may require some level of downstream device assembly, and we’re committed to supporting that vertical integration for our customers, both clinically and commercially.”

“Our ideal customer is one who appreciates the value of contract manufacturing. With an investment of nearly $200 million, we’re not positioning ourselves as a low-cost provider but as a partner offering right-sized, capable capacity. We’re looking for customers who understand and seek quality and capability over mere cost savings.”

Sustainability: a core consideration

Sustainability is a key focus for INCOG, with the company reducing the carbon footprint by integrating device assembly and eliminating the need to ship products off-site.

“Our location in Fishers, a suburb of Indianapolis, has become a hub for life science manufacturing. The establishment of a Life Science Park and the proximity to Stevanato Group, a manufacturer of vials, syringes, and cartridges, allows us to minimise our carbon footprint. This creates a unique opportunity for sustainability-conscious customers.” says Cory.

The importance of long-term planning

Companies should look beyond the immediate 6 to 12 months and consider the growing demand for syringes, especially with the rise of monoclonal antibodies and the GLP-1 market, says Cory.

“GLP-1 is projected to be a $100 billion market by 2030, indicating a substantial increase in syringe consumption. Strategic, long-term thinking will be crucial for success in this evolving landscape.”

“We’re not just planning for the immediate needs but looking one, two, even three years ahead. With our second and third production lines in the pipeline, we’re preparing for the long-term demands of the market. This forward-thinking approach is especially crucial for syringes and cartridges, where longer-term planning is becoming increasingly important.”

Advice for Pharma and Biotech partnerships

When it comes to partnering with a CDMO, it’s essential to look beyond mere capabilities, says Cory.

“The relationship with a CDMO should be more than a transaction; it’s a partnership that extends beyond capabilities and cost. It’s about how issues are resolved, how customer service is approached, and how the company aligns with your long-term goals. This ‘softer side’ of business is often overlooked but is critical for a successful, enduring partnership.”

“The right partnership is about shared vision and trust, knowing that you’ll be working collaboratively for years to come. It’s about choosing a partner you can ‘marry,’ one that will grow with you from clinical phases to commercial scale-up.”

Meet with the INCOG team at CDMO Live. Register for your free ticket.