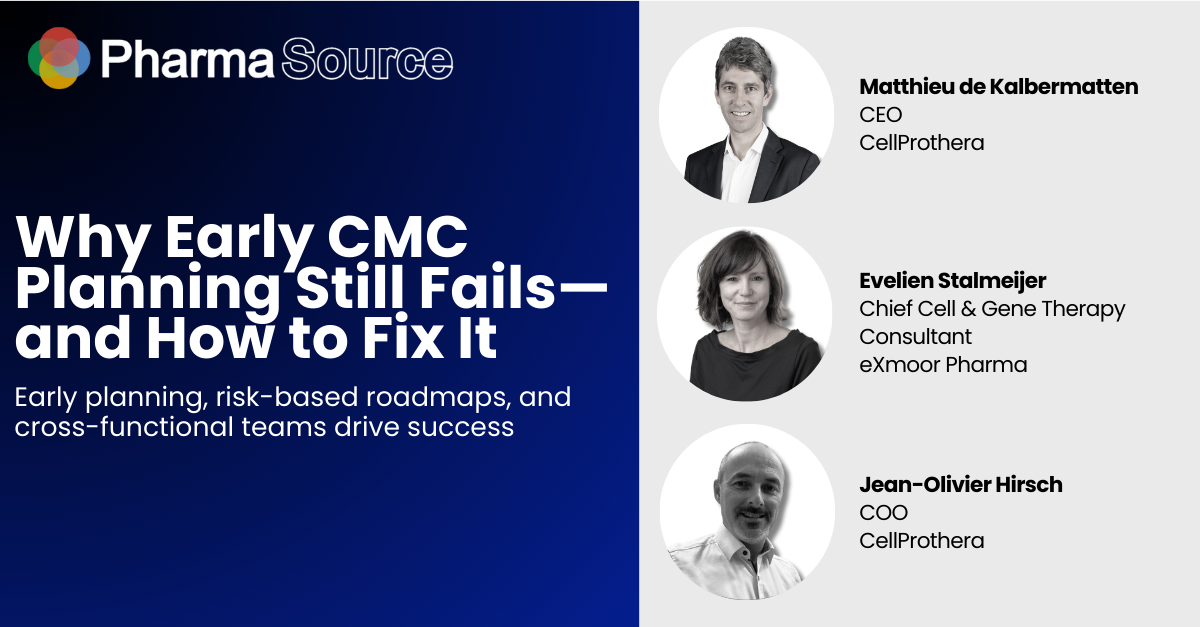

“CMC success is rarely the product of last-minute fixes. It comes from embedding strategic foresight, regulatory awareness, and cross-functional collaboration from day one.” — Evelien Stalmeijer

Evelien Stalmeijer, Chief Cell & Gene Therapy Consultant at eXmoor Pharma, brings deep expertise in CGT manufacturing strategy, helping developers align early-stage decisions with long-term commercial and regulatory goals. She’s joined in this discussion by Matthieu de Kalbermatten, CEO of CellProthera, and Jean-Olivier Hirsch, CellProthera’s COO, who offer strategic and operational perspectives on how pharma and biotech teams can future-proof their CMC approach.

Why Early CMC Planning Still Falls Short

Across advanced therapies and traditional modalities, one theme is clear: early CMC planning is often deprioritised in favour of speed to clinic. But this short-termism can backfire.

Evelien warns that “developers often prioritise short-term cost savings — such as research-grade processes, materials, or facilities — to minimise early expenditure. While this may reduce upfront costs, it frequently leads to significantly higher expenses down the line.”

Matthieu agrees, noting that many teams treat CMC as a static requirement. “When CMC is deferred until later phases, developers often discover that core aspects of their manufacturing approach cannot easily be adapted to meet regulatory expectations.”

This misalignment is especially pronounced in CGT, where manufacturing is highly product-specific and scale-up is inherently complex. Evelien points out that “early decisions, particularly around cell line development, are foundational. Missteps or compromises at this stage can ripple across the entire product lifecycle.”

“By neglecting to embed late-phase and commercial thinking into early development, teams risk building fragile foundations that require costly rework, delay clinical progress, and jeopardise investor confidence.” — Evelien

Three Critical Vulnerabilities

Jean-Olivier highlights three operational blind spots that often emerge when CMC is treated as an afterthought:

- Facility readiness: Achieving cGMP compliance and preparing for inspections is resource-intensive, whether internal or outsourced.

- Process scalability: Small-scale clinical methods rarely translate directly to commercial production, especially for cell therapies.

- Data integrity: Regulators expect complete, traceable records for every batch, with consistent analytical validation.

“Gaps in these areas can delay approval, regardless of clinical outcomes,” Matthieu notes.

A Practical Path Forward

All three experts agree: the solution lies in embedding CMC as a dynamic, cross-functional discipline from day one.

Evelien recommends formalising a risk-based CMC roadmap before critical manufacturing begins. This should include:

- A clear Quality Target Product Profile (QTPP) linking clinical use to manufacturing and analytical needs.

- Regulatory horizon scanning to anticipate the most stringent global requirements.

- Early engagement with regulators to validate reduced-GMP approaches.

- Documented risk assessments for materials, facilities, and analytical methods.

“Seeking scientific advice before adopting non-GMP approaches can prevent costly rework and keep multi-region market access options open.” — Evelien

Meanwhile, Jean-Olivier advocates for operational integration through a cross-functional governance group. This team—spanning R&D, manufacturing, and regulatory affairs—should meet regularly to review progress and anticipate future needs.

“Such integration helps identify potential scaling issues, facility constraints, and documentation gaps early, when solutions are more manageable.” — Jean-Olivier

Matthieu adds that CDMO partnerships must be strategic, not transactional. “Partnering with a CDMO can add valuable expertise, but the relationship must be built on shared timelines, mutual accountability, and transparent data exchange.”

CMC as Strategic Infrastructure

The message from all three leaders is clear: CMC is not a box to tick—it’s the infrastructure that underpins regulatory success, commercial viability, and patient access. By embedding it early, treating it as dynamic, and aligning cross-functional teams around it, developers can avoid the costly pitfalls that continue to plague the industry.

Hear more from CellProthera’s CEO, Matthieu de Kalbermatten, in a recent PharmaSource podcast.