Procurement Operating Models – which is right for your business?

The procurement function plays a critical role in the pharmaceutical industry, where strategic sourcing, cost control, and value creation are paramount.

Choosing the right procurement operating model is crucial for leadership teams to ensure maximum value capture and sustainability.

In this article we summarise some of the main procurement operating models , including centralized, centre-led, hybrid, matrixed, and decentralized models – with advantages and disadvantages for each.

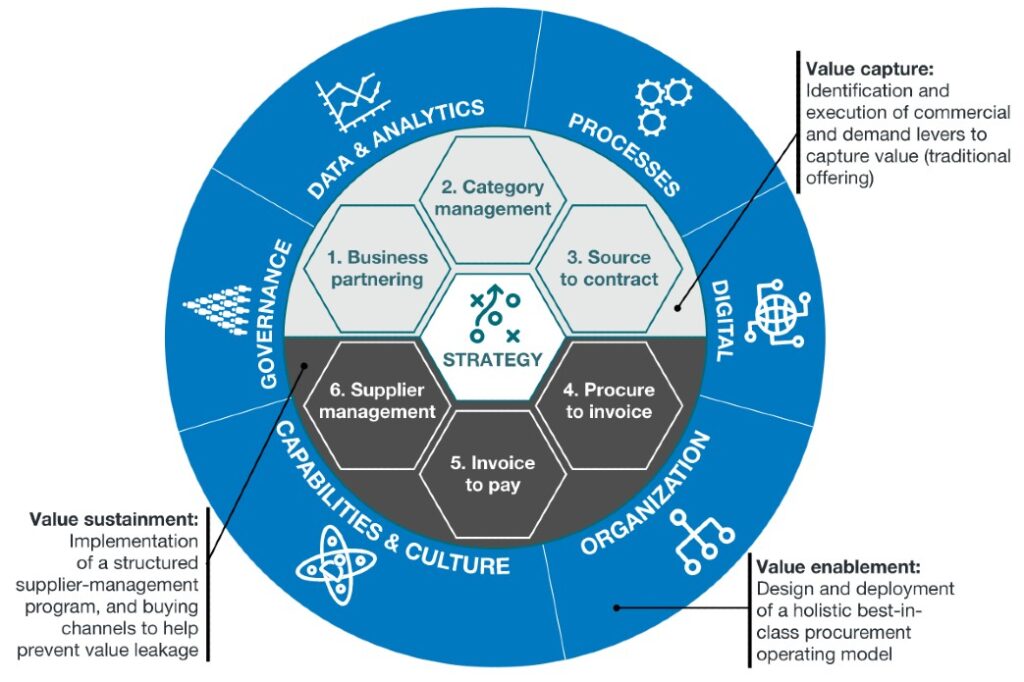

Source: McKinsey

The pharmaceutical industry operates in a complex and dynamic environment, requiring procurement organizations to be agile, strategic, and cost-efficient. Procurement operating models determine how procurement activities are structured and managed within an organization. By understanding the different operating models available, CPOs and executive leadership teams can align their procurement functions with strategic objectives, optimize resource allocation, and drive value across the supply chain.

Understanding Procurement Operating Models

Centralised Model

In a centralized procurement operating model, procurement activities are consolidated under a single central function. This model enables streamlined processes, better negotiation power, and centralized expertise. However, it may suffer from a lack of local market knowledge and agility, limiting responsiveness to local needs.

According to McKinsey & Company, “A centralized procurement operating model can improve efficiency and reduce costs by leveraging economies of scale and standardizing processes across the organization.”

Centre-Led Model

The centre-led procurement operating model strikes a balance between central control and local flexibility. While procurement activities are managed centrally, dedicated resources are allocated to business units. This model allows for central coordination and strategic sourcing, along with local business unit flexibility and responsiveness. However, challenges in aligning goals and objectives and increased complexity in governance may arise.

According to EY, “A centre-led procurement operating model strikes a balance between central control and local flexibility, allowing for strategic sourcing at the centre and localised decision-making at the business unit level.”

Hybrid Model

The hybrid procurement operating model combines elements of centralized and decentralized approaches. It allows for a balance between centralized control over strategic categories and local autonomy for tactical purchasing. The hybrid model offers flexibility to adapt to varying needs but may present challenges in aligning central and local teams.

According to Deloitte, “A hybrid procurement operating model allows for a balance between centralized control and decentralized decision-making, leveraging the strengths of both approaches to optimize value creation.”

Matrixed Model

The matrixed procurement operating model organizes procurement resources based on a combination of category expertise and business units. This model enables in-depth category expertise and specialization, strong collaboration between procurement and business units, and enhanced agility and responsiveness. However, managing matrix relationships and potential resource conflicts and role ambiguity can be challenging.

McKinsey & Company states that “A matrixed procurement operating model enables deep category expertise while maintaining close collaboration with business units, fostering a strategic approach to procurement.”

Decentralized Model

In a decentralized procurement operating model, procurement activities are fully devolved to individual business units. This model empowers local business units to have full control over procurement decisions, fostering agility and responsiveness to local market needs. However, it may result in fragmentation and duplication of efforts, limited leverage in negotiations and cost control, and challenges in aligning strategic objectives.

According to EY, “A decentralized procurement operating model empowers local business units to have full control over procurement decisions, fostering agility and responsiveness to local market needs.”

Which roles should sit in Central Centre of Excellence vs Business Units?

Within the central CoE, roles and skills such as strategic sourcing, category management, technology adoption and implementation, data analytics, vendor management, and procurement strategy development typically reside. The CoE acts as a centre of expertise and ensures standardization, best practices, and strategic direction for the procurement function.

In the business units, roles and skills related to tactical purchasing, supplier relationship management, stakeholder engagement, contract management, and demand forecasting are commonly found. The business units are responsible for executing procurement activities aligned with their specific operational needs while maintaining collaboration and communication with the central CoE.

Strengths and Weaknesses of each model

This table outlining the strengths and weaknesses of different procurement operating models:

Advantages

Disadvantages

Centralised

– Consolidated purchasing power and leverage in negotiations

– Standardization of processes and policies

– Centralized expertise and category management

– Limited flexibility and agility in local market response

– Potential for delays in decision-making due to central control

– Challenges in addressing unique business unit needs

Centre-led

– Strategic sourcing and category management at the center

– Enhanced stakeholder engagement and collaboration

– Potential duplication of efforts and resources

– Increased decision-making complexity and potential conflicts

Hybrid

– Local autonomy for tactical purchasing

– Flexibility to adapt to varying needs

– Potential for duplication and inefficiencies

– Challenges in aligning central and local teams

Matrixed

– Potential for resource conflicts and role ambiguity

– Requires robust governance and clear communication

Decentralised

– Limited leverage in negotiations and cost control

– Challenges in aligning strategic objectives

How a Hybrid approach can combine the best of centralised and decentralised

To leverage the best aspects of centralised and decentralised procurement models, organisations can adopt a hybrid approach that combines the strengths of both models. Here are some strategies to use the best of both:

- Strategic Category Management: Centralise strategic category management functions, such as supplier relationship management, contract negotiations, and global sourcing strategies. This allows for consolidated purchasing power, standardised processes, and expertise in managing critical categories.

- Local Operational Autonomy: Provide business units or local teams with autonomy in tactical procurement activities that are specific to their needs. This allows for local market knowledge, faster decision-making, and responsiveness to unique business requirements.

- Collaborative Governance Structure: Establish a robust governance structure that encourages collaboration between the centralised procurement function and business units. This ensures alignment of objectives, effective communication, and coordination to optimise procurement outcomes.

- Clear Roles and Responsibilities: Define clear roles and responsibilities for the centralised procurement team and the decentralised business units. This clarity helps avoid duplication of efforts, eliminates ambiguity, and promotes accountability at both levels.

- Data Sharing and Analytics: Implement systems and processes for sharing procurement data and analytics between the centralised function and business units. This allows for informed decision-making, identification of trends, and leveraging data-driven insights for strategic procurement initiatives.

- Standardised Policies and Processes: Develop standardised procurement policies, processes, and tools that are applied across the organisation. This ensures consistency, promotes efficiency, and supports compliance while allowing for flexibility in localised execution.

- Continuous Improvement and Learning: Foster a culture of continuous improvement and learning by encouraging knowledge sharing and best practice exchange between the centralised procurement function and business units. This promotes innovation, increases efficiency, and drives value creation.

- Performance Metrics and KPIs: Define performance metrics and key performance indicators (KPIs) that align with organisational goals and are applicable to both the centralised procurement function and business units. This enables tracking of performance, identification of areas for improvement, and recognition of successes.

How to decide which operating model to use

The choice of procurement operating model should consider various factors to ensure alignment with organizational goals and maximize value creation. The following recommendations provide guidance for model selection:

When considering procurement operating models, several key factors should be taken into account. These factors help organizations align their procurement functions with strategic objectives, optimize resource allocation, and drive value creation. The main things to consider include:

1. Organizational Strategy

Understand the overall strategic goals and objectives of the organization. The procurement operating model should align with these strategic priorities to support value creation, cost optimization, risk management, and innovation.

2. Team Size and Spend

Evaluate the size of the procurement team and the organization’s spend on goods and services. This assessment helps determine the level of centralization or decentralization needed to achieve efficiency, economies of scale, and effective resource allocation.

For smaller teams or organizations with limited spend, a centralized or center-led model may be more suitable. These models enable efficient resource allocation, centralized expertise, and cost control. Larger teams or organizations with substantial spend can consider hybrid or matrixed models to balance central control and local flexibility, leveraging category expertise and business unit collaboration.

3. Geographic Complexity

Consider the organization’s geographic footprint and the complexity of its operations across different regions or countries. Geographic diversity may influence the need for local market expertise, responsiveness, and cultural understanding, which can impact the choice of operating model.

In geographically complex environments or when remote working is prevalent, the hybrid or decentralized models offer advantages. They allow for local market knowledge, adaptation to regional nuances, and faster decision-making. Leveraging collaborative technologies and communication tools is crucial to ensure effective coordination and alignment across locations.

4. Technology Readiness

Assess the organization’s readiness and willingness to adopt digital technologies and automation in procurement processes. Some operating models may be better suited for technology integration and leveraging data analytics, while others may require more centralized control for standardization and technology rollouts.

When rolling out technologies, such as digital procurement platforms or automation tools, a centralized or center-led model may be preferable. This ensures consistent implementation, standardization, and maximum utilization of technology across the organization. Hybrid and matrixed models can also be effective if supported by strong governance and coordination mechanisms.

5. Supplier Landscape

Analyze the organization’s supplier base and the nature of relationships with suppliers. Consider whether the organization relies on a limited number of strategic suppliers or engages with a broader range of suppliers. This assessment can influence the need for central control or local flexibility in procurement decision-making.

6. Category Management

Evaluate the complexity of the organization’s procurement categories. Some categories may require deep expertise and centralized control, while others may benefit from local business unit involvement and specialized knowledge. Consider the balance between central coordination and category-specific requirements.

7. Risk Management

Assess the organization’s risk appetite and the criticality of risk management in procurement. Centralized models may provide better visibility and control over supplier risks, while decentralized models may allow for more localized risk mitigation strategies.

8. Stakeholder Alignment

Consider the level of stakeholder involvement and collaboration required in procurement processes. Some organizations may benefit from a centralized or center-led model that promotes cross-functional collaboration, while others may prefer decentralized models that empower business units to make procurement decisions aligned with their specific needs.

Organizational Culture: Understand the organization’s culture and decision-making style. Some organizations may have a strong preference for centralized control and standardization, while others may prioritize empowerment and autonomy at the business unit level. Aligning the operating model with the organizational culture can enhance adoption and effectiveness.

Scalability and Flexibility: Consider the organization’s growth plans and the ability of the chosen operating model to scale and adapt to changing business needs. Ensure the model can accommodate future expansions, acquisitions, or changes in market dynamics without significant disruptions.

Indirect procurement, which includes categories such as IT, facilities, and marketing, is often centralized due to the potential for economies of scale and synergies. On the other hand, direct procurement, involving raw materials and manufacturing components, may benefit from decentralization to align with specific business unit needs and foster supplier relationships.

By considering these factors, organizations can make informed decisions when selecting a procurement operating model that best suits their unique needs, promotes efficiency, and enables the capture and sustenance of maximum value.

For example:

For a large big pharma company with over 10,000 employees located around the globe, a hybrid or matrixed procurement operating model is recommended.

This model allows for a balance between centralized control and local flexibility, which is particularly beneficial for organizations of this scale. The hybrid model enables centralization of strategic category management, supplier relationships, and global sourcing strategies to achieve economies of scale, negotiate favorable contracts, and drive consistency. Simultaneously, it provides autonomy and operational decision-making authority to local business units to adapt to regional nuances, leverage local market knowledge, and ensure responsiveness. The matrixed model supports collaboration, cross-functional alignment, and the sharing of expertise across the organization, enhancing efficiency and innovation.

For a small biotech startup a centralised or centre-led procurement operating model is recommended. Given the limited scale and resources of a small startup, a centralised model allows for efficient resource allocation, cost control, and consolidated expertise. Centralized procurement can help leverage purchasing power, negotiate favourable terms with suppliers, and ensure consistent processes across the organisation.

A centre-led model could be suitable, where the procurement function operates as a centre of excellence (CoE) supporting the business units with strategic sourcing, category management, and technology adoption. This model allows for collaboration and guidance from the CoE while empowering business units to handle tactical purchasing aligned with their specific needs.

To capture the value available from digital technologies, data analytics, and the application of machine learning and AI in procurement, organizations should adopt operating models that embrace digitalization. Centralized or center-led models facilitate data-driven decision-making, advanced analytics, and the integration of digital platforms. Collaboration between the CoE and business units is crucial for successful implementation and utilization of these technologies.

Centralized or center-led models facilitate data-driven decision-making, advanced analytics, and the integration of digital platforms. Collaboration between the CoE and business units is crucial for successful implementation and utilization of these technologies.

How to make the selected model work

Once a procurement operating model is chosen, it is essential to establish effective processes and ways of working to ensure its success. Key considerations include:

Stakeholder Engagement and Communication

Frequent and proactive stakeholder engagement is vital to secure buy-in and alignment with the chosen model. Regular communication channels, such as town hall meetings, workshops, and dashboards, should be established to update stakeholders on procurement initiatives, share successes, and address concerns. Collaboration and transparency build trust and ensure that all stakeholders understand the benefits and expected outcomes.

Processes and Ways of Working

Clear governance frameworks, decision-making protocols, and performance metrics should be defined and communicated across the organization. This ensures accountability, consistency, and continuous improvement. Regular meetings between the CoE and business units, such as operational reviews and cross-functional workshops, facilitate knowledge sharing, problem-solving, and the exchange of best practices

Responses