Quality Oversight Plans in Pharma: A Comprehensive Guide to Implementation

In today’s complex pharmaceutical manufacturing landscape, where outsourcing has become increasingly prevalent, a robust quality oversight plan is essential for ensuring consistent product quality and regulatory compliance.

Quality Oversight Meaning

Quality oversight in pharmaceutical manufacturing encompasses the systematic monitoring, evaluation and control of quality systems across manufacturing operations, with particular emphasis on contract manufacturing organisations (CMOs). It goes beyond traditional quality control and quality assurance, representing a holistic approach to ensuring product quality, patient safety and regulatory compliance throughout the manufacturing network.

At its core, quality oversight involves maintaining vigilant supervision of all quality-related activities, from raw material testing to finished product release. This includes monitoring manufacturing processes, reviewing batch documentation, managing deviations and investigations, and ensuring compliance with current Good Manufacturing Practice (cGMP) requirements.

The concept has evolved from simple audit-based approaches to become a more dynamic, continuous process that requires real-time monitoring and data-driven decision-making.

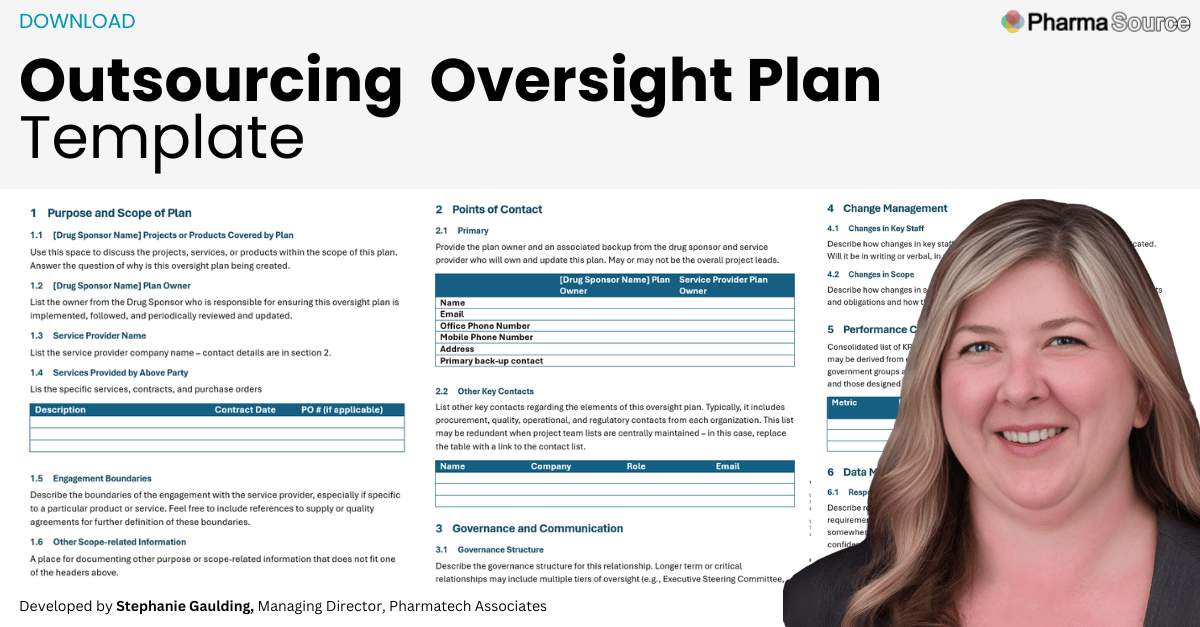

Quality Oversight Plan [Download]

Outsourcing oversight plans provide a structured approach for managing and monitoring outsourced activities.

The plan ensures that outsourced services (such as clinical trials, manufacturing, or regulatory affairs) meet quality, compliance, and performance standards.

1 Purpose and Scope of Plan

2 Points of Contact

3 Governance and Communication

4 Change Management

5 Performance Criteria

6 Data Management

7 Knowledge Management

8 Risk Management

Download your copy

“Quality oversight isn’t just about compliance – it’s about building successful partnerships and driving down costs,”

Stephanie Gaulding Tweet

A comprehensive quality oversight plan serves as the backbone for managing quality across external manufacturing operations. The plan should begin with clear definitions of roles, responsibilities and expectations between the sponsor company and CMOs. This includes establishing governance structures, communication channels and escalation pathways for quality issues.

The plan should detail specific oversight activities, including the frequency and scope of quality reviews, audit schedules and performance monitoring requirements. It must also outline how quality metrics will be collected, analysed and reported, ensuring consistency across different manufacturing sites and geographies.

Risk assessment forms a crucial component of the plan, helping to determine the appropriate level of oversight for different processes and products. This risk-based approach enables companies to allocate resources effectively, focusing more attention on high-risk areas whilst maintaining appropriate oversight of lower-risk activities.

Another essential element is the establishment of quality agreements with CMOs. These documents should clearly define quality expectations, responsibilities and communication protocols. They should also specify requirements for handling deviations, changes and out-of-specification results, ensuring alignment between sponsor and CMO quality systems.

Quality Oversight Officer

The Quality Oversight Officer plays a pivotal role in implementing and maintaining the oversight programme. This senior position requires a unique combination of technical expertise, leadership skills and strategic thinking. The officer must possess deep understanding of GMP requirements, regulatory expectations and quality system management.

Key responsibilities of the Quality Oversight Officer include developing and implementing quality oversight strategies, managing relationships with CMOs, coordinating internal quality teams and serving as the primary point of contact for quality-related matters. They must also ensure effective communication between various stakeholders, including regulatory authorities, internal teams and external partners.

The officer should possess strong analytical skills to interpret quality data and trends, identifying potential issues before they become significant problems. They must also demonstrate excellent project management capabilities to coordinate multiple oversight activities across different sites and time zones.

Success in this role requires the ability to influence without direct authority, as they often need to drive quality improvements through partnership rather than traditional hierarchical relationships. The officer must also stay current with evolving regulatory requirements and industry best practices, ensuring the oversight programme remains effective and compliant.

For more insights into Quality Oversight in pharma listen to this podcast episode with Stephanie Gaudling