“Temperature-critical products are transforming the pharmaceutical supply chain, with 50 percent of FDA-approved drugs now requiring precise thermal management,” says Jens Mangelsen, Chief Commercial Officer of Intelsius.

Jens Mangelsen, Chief Commercial Officer at Intelsius, brings extensive expertise in pharmaceutical packaging solutions. With a focus on temperature-controlled packaging, Mangelsen leads product development across multiple markets for this specialised logistics provider.

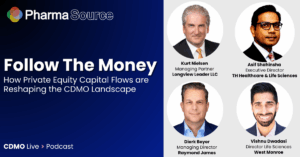

In the latest PharmaSource podcast, Mangelsen unpacks the critical challenges and innovative solutions reshaping pharmaceutical cool chain logistics, offering insights into how companies can optimise their temperature-sensitive supply chains.

The Rising Importance of Temperature-Critical Logistics

The pharmaceutical industry is experiencing a seismic shift towards temperature-sensitive products. Biologics, personalised medicines, and cell therapies are increasingly dependent on precise thermal management during transportation.

Key statistics highlight this trend: “The FDA approved 50 percent of drugs as temperature-critical in 2018, and this number continues to grow,” Mangelsen explains. This evolution demands robust, transparent cool chain solutions that ensure product integrity from manufacturer to patient.

The complexity of these temperature-sensitive products cannot be overstated. Modern pharmaceutical developments like personalised medicine and gene therapies often require extremely precise temperature control. A deviation of just a few degrees can render millions of dollars worth of life-saving medication completely ineffective.

The Future of Pharmaceutical Logistics: A Comprehensive Vision

Mangelsen’s insights reveal a profound transformation in pharmaceutical logistics that encompasses four critical dimensions of innovation and strategic thinking.

1. Collaborative Ecosystem Emergence

The future will be defined by unprecedented collaboration. Rather than working in isolated silos, service providers will create integrated offerings that provide comprehensive solutions. This means logistics companies, technology providers, packaging manufacturers, and pharmaceutical companies will develop more interconnected, symbiotic relationships.

Central to this collaborative approach is the evolution of reusable packaging. While initial investments are higher, the long-term benefits are substantial. “We’ve seen scenarios where overall savings reach 40-50 percent compared to single-use packaging,” Mangelsen reveals. The economic model is compelling – packaging that can be reused 80-100 times drives down per-shipment costs to less than 10 percent of original single-use packaging expenses.

The advantages extend beyond financial savings:

- Significantly reduced CO2 emissions

- Lower waste generation

- More sustainable logistics model

- Improved asset utilization

2. Digital Transformation and Predictive Intelligence

Digital services will move from being supportive technologies to becoming core strategic assets. Emerging technologies like IoT, real-time monitoring, and AI-driven predictive analytics are creating more transparent, efficient supply chains.

“Real-time monitoring provides immediate data availability, eliminates data loss, and creates comprehensive audit trails,” Mangelsen notes. These technologies enable:

- Instant visibility into supply chain movements

- Predictive maintenance for logistics infrastructure

- Dynamic routing optimisation

- Comprehensive risk management tools

The ability to track packaging in real-time allows companies to:

- Minimise idle times of packaging

- Optimise fleet sizes

- Speed up packaging reuse cycles

- Provide immediate access to comprehensive shipment data

3. Sustainability as a Strategic Imperative

Sustainability will transition from a corporate social responsibility initiative to a core business strategy. This involves:

- Widespread adoption of reusable packaging

- Developing fully recyclable single-use solutions

- Integrating recycled and upcycled materials

- Implementing greener logistics practices

- Reducing carbon emissions across transportation networks

Particularly in packaging, this means moving beyond single-use plastics to more sustainable alternatives. Companies are exploring packaging solutions made from recyclable materials, focusing on reducing environmental impact while maintaining the critical temperature control requirements of pharmaceutical products.

4. Economic Reimagination

The economic model of pharmaceutical logistics will fundamentally shift. Cost reduction will be achieved through:

- Advanced asset management technologies

- Optimised packaging lifecycles

- Reduced waste

- More efficient transportation networks

Intelsius is championing reusable packaging as a game-changing approach for pharmaceutical logistics. While initial investments are higher, the long-term benefits are substantial.

“We’ve seen scenarios where overall savings reach 40-50 percent compared to single-use packaging,” Mangelsen reveals. The advantages extend beyond financial savings:

- Packaging can be reused 80-100 times

- Significantly reduced CO2 emissions

- Lower waste generation

- More sustainable logistics model

Though reusable packaging might cost twice as much initially, its ability to be used multiple times drives down per-shipment costs. Companies can expect to reduce packaging expenses to less than 10 percent of their original single-use packaging costs.

The goal is not just to reduce costs, but to create a more intelligent, responsive, and sustainable logistics ecosystem that can adapt to the increasingly complex demands of modern pharmaceutical development.

Mangelsen’s parting advice encapsulates this transformative vision: “Invest time in exploring reusable packaging solutions. The initial complexity pays off in the long term.”

For more information read temperature-controlled packaging explained.