DOWNLOAD

Sustainability by Design in API Manufacturing

Download Case Studies Showing 85% Reduction in the Carbon Footprint

Download the White Paper

A Practical Blueprint for Sustainable Small Molecule Manufacturing

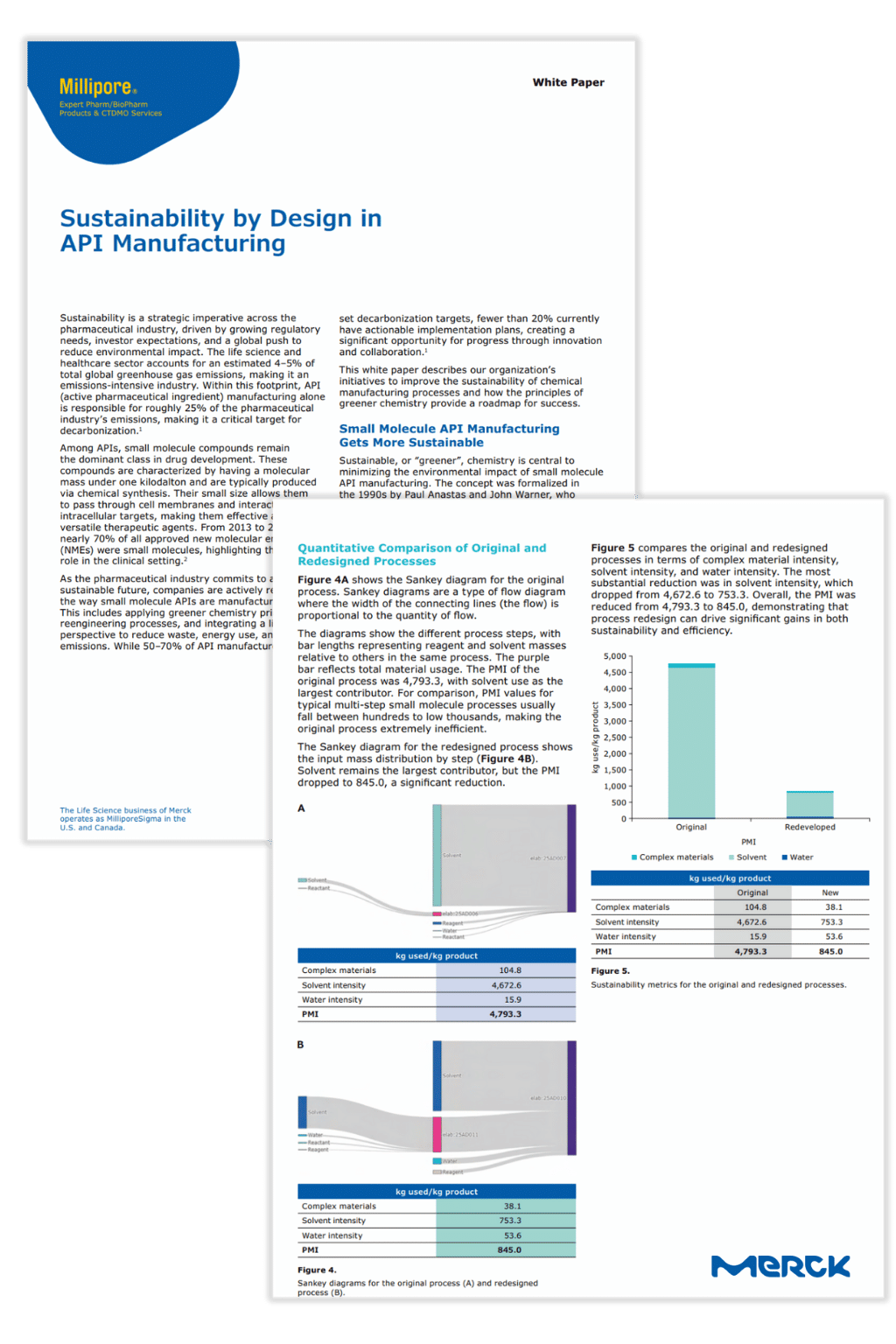

The pharmaceutical industry accounts for 4–5% of global greenhouse gas emissions. API manufacturing alone contributes around 25% of that footprint. This white paper outlines Merck’s real-world process improvements using green chemistry principles, smart synthesis design, and advanced analytical frameworks such as DOZN™ and GreenSpeed.

Inside This White Paper:

- Case studies showing PMI reduction from 4,793.3 to 845.0 and from 12,339.5 to 181.0.

- How continuous flow manufacturing reduced carbon footprint by 20% and 85% in different processes.

- DOZN™ Quantitative Green Chemistry Evaluator and GreenSpeed platforms.

- The 12 Principles of Green Chemistry framework and application.

- Process redesign approaches, including synthetic route optimization and column elimination.

- Yield improvements from 39% to 66% and from 65% to 75%.

25%

API Manufacturing’s Share of Pharma Emissions

70%

New Drugs are Small Molecules (2013-2023)

12

Principles of Green Chemistry Applied

Proven Results from Real Projects

These case studies demonstrate the dramatic improvements possible through strategic process redesign and green chemistry implementation.

Process 1

Multi-Step Synthesis Redesign (Original vs. Redesigned Route)

PMI Reduction 4,793 → 845

Overall Yield 39% → 66%

Solvent Intensity 83.9% reduction

Product Purity >99.5% maintained

Process 2

Column-Free Purification Strategy (Original vs. Redesigned Route)

Continuous Flow

Process Intensification Examples

Tools Driving Sustainable Process Innovation

- GreenSpeed: Real-time PMI, water, solvent, and CO₂ analysis linked to electronic lab notebooks.

- DOZN™: Quantitative green chemistry tool measuring alignment with the 12 Principles of Green Chemistry.

- Synthia™ Retrosynthesis: AI-enabled smart route design supporting greener synthetic pathways.

Get the Full White Paper

Access Merck’s real-world sustainability improvements, quantitative case studies, PMI analysis, and continuous-flow redesign insights — all backed by rigorous experimental data.

The life science business of Merck KGaA, Darmstadt, Germany, operates as MilliporeSigma in the US and Canada.