- Almac Group has completed a multi-million-pound expansion of bioavailability enhancement capabilities at its Charnwood, UK, facility.

- The investment includes new spray drying technologies and expanded analytical laboratories to support advanced formulation solutions.

Almac Group has announced the completion of a multi-million-pound expansion of its bioavailability enhancement capabilities at its Charnwood, UK site. The investment, made by Almac Pharma Services, aims to address challenges around solubility and meet increasing global demand for advanced formulation solutions.

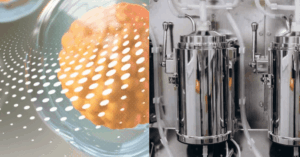

The expansion includes the installation of Buchi S300 and GEA PSD1 closed-loop spray drying technology, alongside extensive upgrades to the facility’s analytical laboratories. These technologies complement existing capabilities in liquid capsule filling and non-sterile oral liquid formulation, while also supporting potent-handling operations at the site.

The new capacity builds on Almac’s long-standing expertise in pre-clinical bioavailability and amorphous solid dispersion development. The company continues to provide a range of approaches, including spray drying, melt extrusion, particle engineering, and advanced analytical services.

James Hurst, VP Operations and Charnwood Site Head, Almac Pharma Services, said: “This investment is a direct response to the growing demand for sophisticated formulation solutions. Spray drying is a cornerstone technology for enabling next-generation therapeutics, and our expanded capabilities ensure we remain at the forefront of pharmaceutical innovation.”

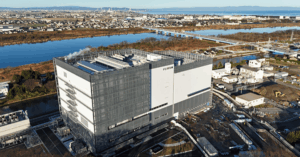

This announcement follows Almac’s £11 million investment in global analytical capabilities and the recent opening of a £65 million, 100,000 square foot commercial manufacturing facility at its Craigavon headquarters in Northern Ireland.